On the way to Manufactory 4.0

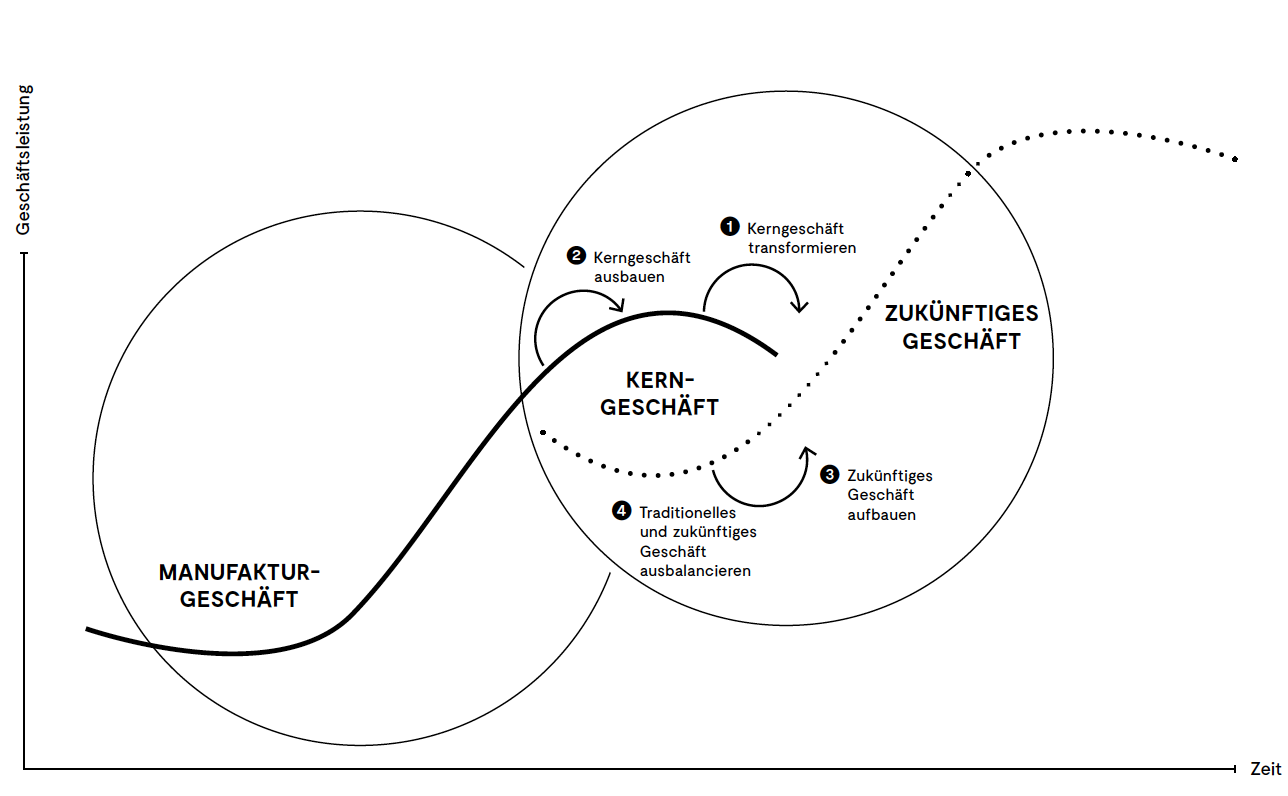

The German Craft Council accompanies manufactories in their transition to the digital world. The introduction of new technologies in manufactories is not without risk, because it touches the core of the manufactory’s self-understanding. When implementing a digital strategy, it makes sense to proceed carefully and in controlled steps.

On the way to Manufaktur 4.0.

The German Craft Council networks the actors who can help each other. This is necessary. Although craftsmanship has once again been attracting a great deal of attention in recent years, manufactured products have become en vogue and synonymous with “quality”. But it must not be forgotten that despite all the (sometimes transfiguring) recognition, manufactories are most severely affected by the political and economic consequences of globalisation.

Worries about young talent, competition with industrially manufactured competing products or the monopolisation of trade are leading to an economic reality in which manufactories find it difficult to survive. The German Craft Council bundles the interests of manufactories and workshops in Germany in order to form a counterweight to globally active companies and to strengthen the local economy.

It is important for the manufactories to maintain the environmental conditions that support them. They want to develop innovations that drive them forward. Many want to reach buyers in other countries, but continue to produce in Germany, which is not a matter of course. The Design Forum can work to improve the framework conditions that make this possible.

Quo vadis Manufaktur?

The future of manufactories stands and falls with their ability to find a good balance between tradition and new paths. Especially the younger generation sees technology as an opportunity to make processes more efficient in order to start new creative processes. Craftsmanship and modern technologies complement each other. The digitalisation of design, manufacturing and distribution methods is bringing production and design closer together again. The separation of these areas, which emerged in the course of industrialization, seems to be dissolving today. The training of creative craftsmen should recognise the potential of global networking and, in future, build up a complex knowledge profile for young designers: with qualifications in technological, craft, economic and creative aspects. The German Craft Council aims to create a new, self-confident professional identity for craftsmen and designers who work regionally and are internationally trained and networked.

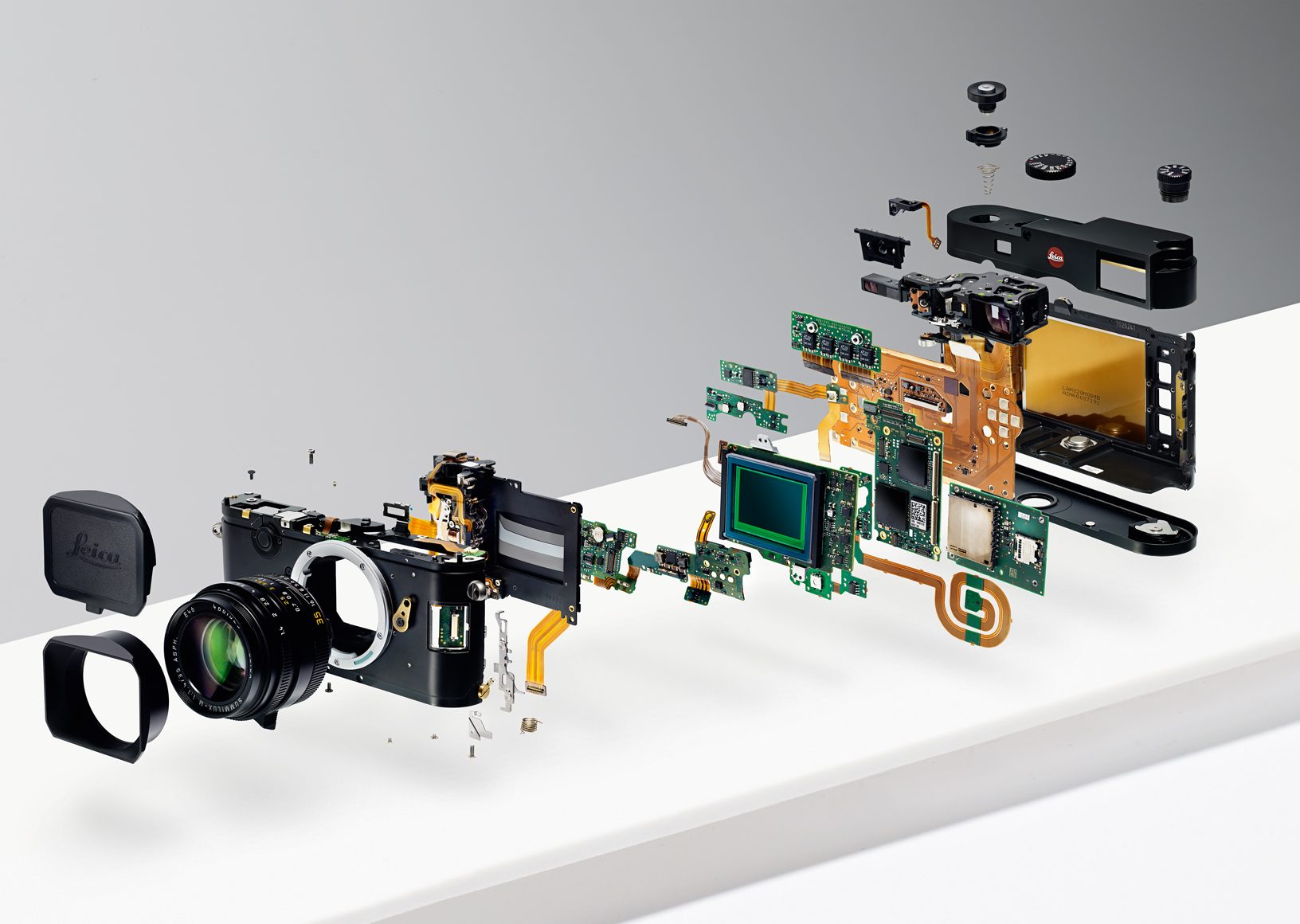

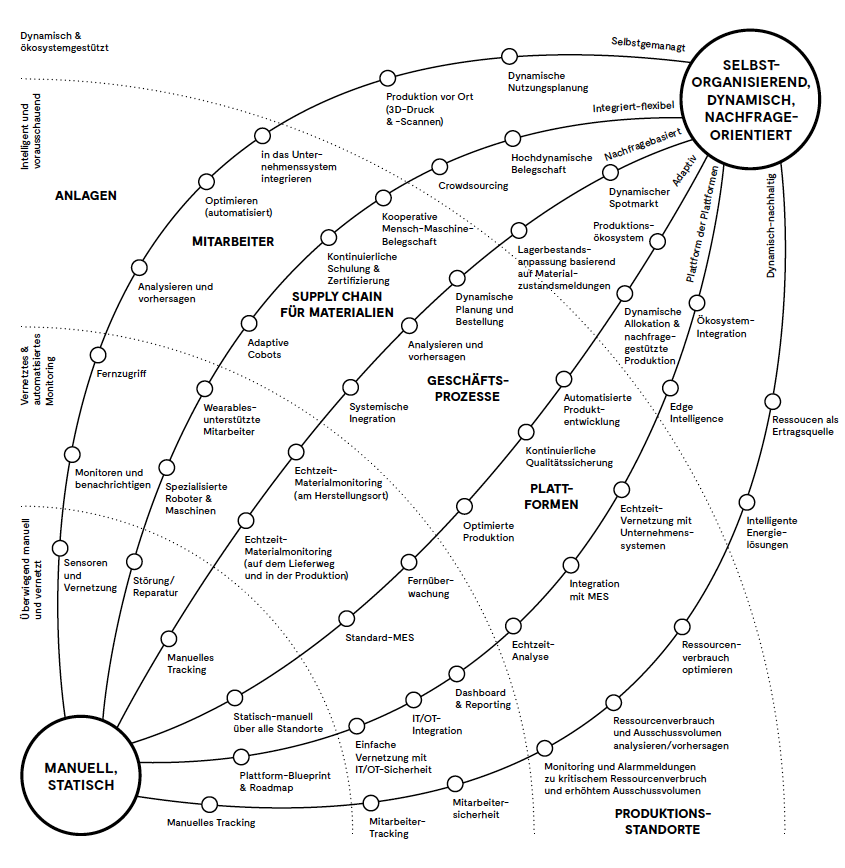

Knowledge of the processing and machining of various materials is fundamental for designers and manufacturers today. In conjunction with modern technologies such as reverse engineering (digitisation), CAD, virtual reality and today’s additive tooling processes (rapid tooling), the process chain within product development is improved. Furthermore, the digital interface of generative manufacturing machines (Rapid Manufacturing) — such as the various 3D printing processes and their automated manufacturing processes — enables decentralized, geographically independent production (Cloud Producing).

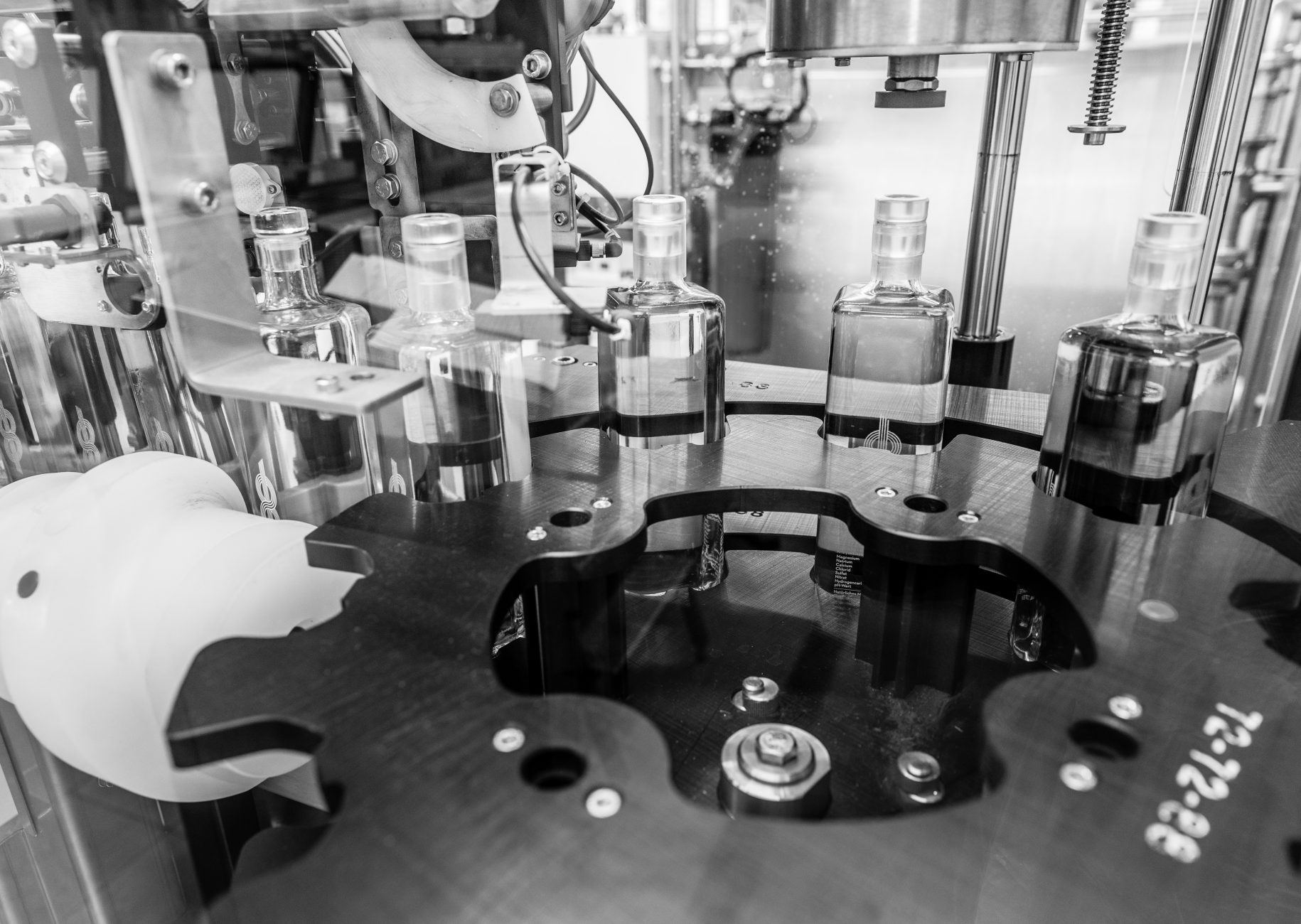

The use of these processes, which the Master Council summarizes under the catchword “Manufactory 4.0”, makes economic sense, especially for the production of very small, precise components in variable quantities, for unique pieces in jewellery, watches, porcelain or in small series production or the individual production of parts with a high geometric complexity, also with additional function integration.